Primary Lubrication Systems

Novel lubrication systems for high DN, single and short mission bearings

The Problem

Conventional lubrications systems can be the bottleneck in your limited life engine performance

Traditional oil and fuel/lube delivery systems used in limited life engines incorporate a bulky, centralized assembly with multiple sourced components leading to increased weight, supply chain complexity, and excess engine design modifications.

- Heavy Lubrication System

- Complex Supply Chain

- High Development Cost

- Low Efficiency

- Many Potential Failure Points

Our solution

Application Benefits

- Decreased Weight and Cost

- Increased Storage Life

- Improved Performance and Reliability

- Specialized Formulations

Zulu Pods presents a new, revolutionary approach to limited life engine design: the ZPOD.

Zulu Pods’ proprietary oil delivery system features a decentralized, self-contained, hermetically sealed unit capable of developing pressure independent of a traditional central pump, plumbing, and reservoir. Limited life engine designers are now afforded performance optimizing benefits previously constrained by traditional lubrication systems.

Watch the video below to visualize the ZPOD system in a short duration missile application.

Primary lubrication applications

Several common applications are listed below. Our Engineering team can develop custom pod solutions tailored to any limited life engine configuration.

ZPODs are able to develop fluid pressure independent of a central pump or piping, and can be installed in a static configuration to deliver lubricant to multiple bearings (red) from a single pod. In this application, the front pod (gold) is occupying unused interstitial space in the nacelle at the FWD engine bulkhead.

ZPODs are able to develop fluid pressure independent of a central pump or piping, and can be installed in a dual configuration to deliver lubricant to both the FWD and AFT bearings (red). Here, the pods (gold) are integrated both in the unused interstitial space in the nacelle at the FWD engine bulkhead and the tail cone.

A single, dynamic ZPOD (highlighted gold) can be integrated within the jet engine rotor shaft. Once the stored lubricant is released from the ZPOD, the rotating shaft is used as a pump to transport lubricant to either the FWD or AFT bearing (highlighted red).

The dual ZPOD dynamic application features two pods (highlighted gold) installed inside the center of a jet engine rotor shaft. Once the stored lubricant is released from its storage, the shaft is used as a pump to transport the lubricant to the FWD and AFT bearings (highlighted red).

Limited life engine design teams have broader options when deciding where the lubrication system should live. With the ZPOD system, custom tailored pods can occupy interstitial spaces - volumes within the engine that are normally unused.

In this application, the inlet cone (gold) houses a dynamic, annular (ring-like) ZPOD that delivers fluid to the bearing working zone.

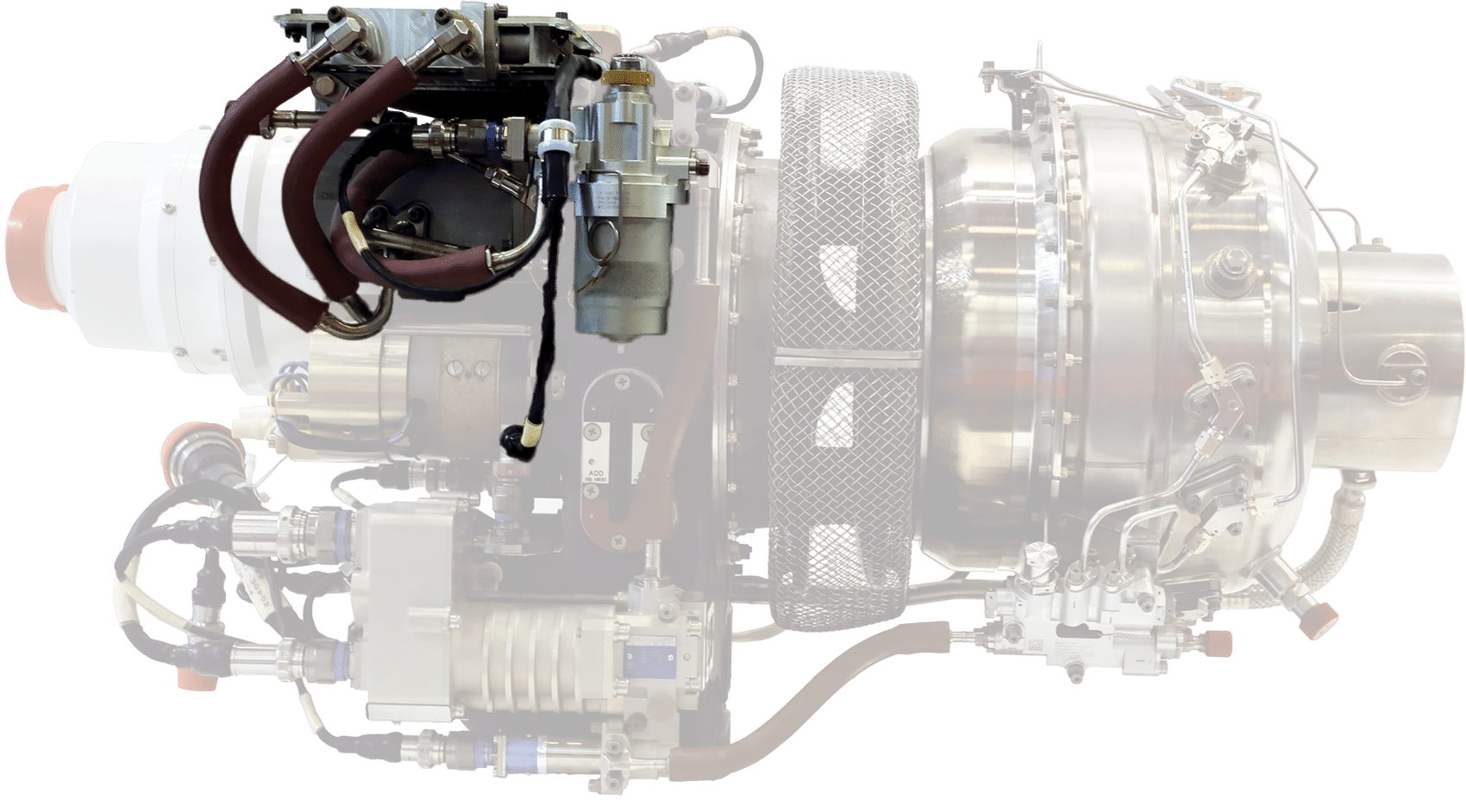

A ZPOD system can work as a fuel system, and can be designed to replace traditional fuel systems. This solution is retrofittable, affords faster start times while eliminating fuel interruptions, and can reduce parts count by up to 54%. In this application, the fuel pod is installed externally.

Applications for ZPOD technology extend beyond the examples listed above. Our R&D Engineering team can develop custom solutions that include the delivery of different liquids in addition to lubricants, customized size and fittings, and additional capabilities. Contact us to begin technical discussions.